- Recent Updates

- Colpoy's Bay

- Colpoy's Bay Introduction

- Spragge's Hill

- The Kalbfleisch House

- The Kalbfleisch Dock

- The Kalbfleisch Marina

- Whicher's Sawmill

- The Wrecks Near Whicher's Mill

- Frame's Falls and John Wood's Grist Mill

- Albemarle Street

- Hughenden and Whicher's Store

- The Community Hall

- The Forest Home Hotel

- The Colpoy's Bay Schoolhouse

- The Colpoy's Bay Church

- Edgehill Cemetery

- Colpoy's Bay From the Air

- A Glimpse of the Past

- Wiarton

- Berford Street

- Berford St. Part 2

- Berford St. Part 3

- Wiarton Harbour

- Bluewater Beach

- Caframo Ltd. and Wiarton Cement Works

- Wiarton Beet Sugar Factory

- Wiarton's Hotels

- Wiarton's Schools

- Wiarton's Banks

- Grand Trunk Railway Station

- The Wiarton Fish House

- The Wiarton Fish Hatchery

- Wiarton's Berford Theatre

- The Wiarton Woolen Mills

- Wiarton's Furniture Industry

- Wiarton's Hospital

- Wiarton's War Memorial

- Wiarton's Town Hall

- Wiarton's Newspapers

- Wiarton's Grist & Flour Mills

- Wiarton's Sawmill Industry

- Wiarton's Gateway

- Connecting Passages

(Links) - Present-day Map

of Colpoy's Bay - Colpoy's Bay

Lot Map (1870)

Wiarton Timeline- Present-day Map

of Wiarton - Bibliography

- About the Author

- Site Map

(use if menu doesn't work) - Tell me your impressions!

Caframo Ltd. and the Wiarton Cement Works

Along the southern shore of Colpoy's Bay sits Caframo Ltd., a a successful multi-generational manufacturing company built on the remains of what was a massive, short-lived cement factory.

Known initially as the Colonial Portland Cement Company, the firm was incorporated with $250 000 of capital in 1901 to create cement using stone from White Cloud Island (one of three islands at the mouth of Colpoy's Bay) and marl (a type of sandstone) found along the shore of the bay. The cement was created using a certain process patented in England in 1824 as "Portland Cement". According to the Portland Cement Association, 98% of the cement currently mixed in the US uses this formulation.

Newspaper accounts of the day praised the factory's construction saying, "It is doubtful if an earthquake would jar the main building and long after the rest of us have vanished away these structures will probably remain." A very prophetic statement, indeed.

Despite the tremendous size of the operation and the fanfare with which it was born, the Colonial Portland Cement Company suffered within an industry of excess production, falling prices and huge amalgamations. The company was forced to fold at the beginning of 1909. Always optimistic, the Echo newspaper exclaimed that the company "never had a fair chance" due to weak demand at the time production began.

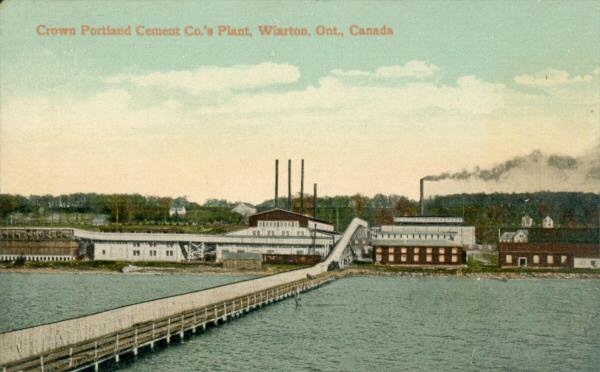

Wiarton's cement factory received a second chance for success when it was reorganized under the name "Crown Portland Cement Co." in June of 1909. Following extensive upgrades to improve efficiency, reduce costs and, ultimately, compete with other cement firms, the cement factory began running again at the end of July.

The productivity of the plant was said to be so superior as to produce with 75 men what is typically produce with 125-150. As is apparent, it consisted of several buildings including the main rotary building, the powerhouse, a boiler house, a coal grinding building and a dry grinder. Interestingly, the company also privately constructed a 3.5 mile rail line between Wiarton and the marl beds government support. (The raised land from this railway is still visible today.) Following the company's 1909 reorganization, it also featured the world's longest conveyor belt. (It was used to deliver stone taken by barge from White Cloud Island.)

Figure W6A below shows three views of the Wiarton cement plant. The top image is a rare photo of the plant still under construction, reflected in the tranquil waters of Colpoy's Bay. Taken sometime between May 1904 and December 1907, several key features of the plant have yet to be erected, including the smokestacks, the water tank and the railway track on the pier. The other two images in Figure W6A depict the Crown Portland Cement Company in its prime. The middle image shows most of the key features that were missing in the top image. Note also the small train engine and the conveyor belt on the pier. The bottom image of Figure W6A is from a postcard and shows a wider view of the middle image.

Figure W6A: The Wiarton cement plant (about 1905 and 1910).

In June of 1909, the firm issued a new series of debentures to pay for the extensive alterations completed following the reorganization. With the price of cement on the rise, the outlook for Wiarton's cement plant appeared to improve. By 1911, the factory was taking on new employees and the Wiarton Echo newspaper raved about the prospects for continued success of the plant, stating, "The outlook for the cement business is exceptionally good."

The following year, 1912, Wiarton made an attempt to annex the factory (and its valuable tax payments) from Keppel Township. However, Keppel Township fought the annexation and in the end, the bid was turned down. The matter was moot in the end anyway, because the Crown Portland Cement Company fell abruptly into receivership in August of 1912.

Again, the Wiarton Echo remained optimistic, urging the company to be wound up so the factory could reorganize once more and run again in the Spring of 1913. As winter came and negotiations continued among the defunct company's shareholders, the Echo suggested that local citizens raise the capital necessary to run the cement works. By March, however, the full picture was visible. The factory had built up significant debt and lost a large amout of money the previous season. The firm then entered liquidation. In combination with the Wiarton Beet Sugar Co. failure some seven years before, the brutal demise of the cement works dealt Wiarton an industrial blow it never quite recovered from.

For five years, the buildings of the cement works stood empty. The expensive machinery was liquidated to junk dealers for a tiny fraction of its original cost and the property was left to a trust company. Any remaining machinery (including the rails and small locomotive used to transport the marl to the factory) was sold off piecemeal during that time, to cover property taxes. Finally, in 1918, Wiarton decided to wipe its slate clean. It was announced that steel in both the beet sugar factory and the cement works would be sold for scrap. So furious were the firm's local investors that they took the massive buildings to ruins in an attempt to wean out every bit of steel. Only empty hulking walls remained, as visible in the top image of Figure W6B below, taken from a distance in 1919. The Echo announced the event with another taste of unknowingly accurate foresight: "From now on, generation after generation, and perhaps until Gabriel blows his horn, men and women and children will gaze at the walls of the cement factory, for they were built for eternity."

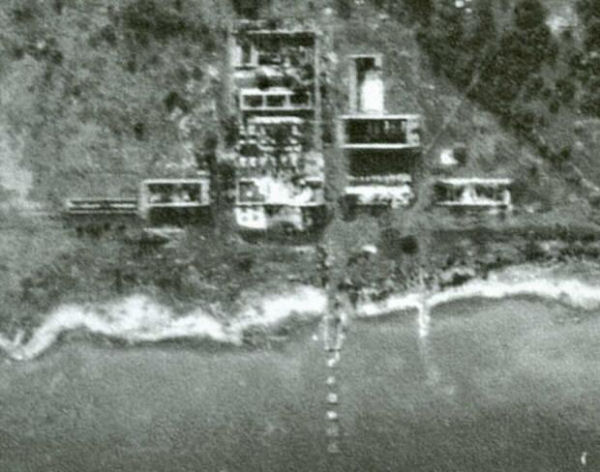

Figure W6B: Two views of the Crown Portland Cement factory ruins (c. 1919, 1950).

Once the cement company closed, its buildings were left to the elements. The bottom image of Figure W6B gives an aerial view of the ruins in 1950. Based on dimensions given in the newspaper when the factory opened, I venture to guess the purpose of each building. Note at the bottom of the picture, the pilings for the massive dock and conveyor belt. The dark line of grass at right shows the path the trains used to travel. The track led trains from Wiarton (toward the right) to the marl beds down the shore (to the left). Trains brought marl several kilometers down the shoreline (beyond the left of this picture) depositing it, I believe, in storage bins (the long narrow structure) at far left. My research suggests that the white building toward the left was the temporary stockhouse (storage building). Dominating the grounds at centre was the massive Main Rotary Building, containing more than twice the square footage of any other building on site. At top right was the Powerhouse with the boilerhouse at the rear. The Coal Grinder and Dry Grinder buildings sat near the train tracks along the shoreline toward the right (although I'm not sure which building was which).

Given the solid construction of most of the cement works buildings, it is not surprising that, after forty years of neglect, most of the damage to the structures came from the actual scrapping of metal in the buildings, not from exposure to the wilderness. Indeed, this was one of the main reasons that drew some German industrialists to purchase the ruins in 1954. Despite their age, the massive walls of the cement works would once again serve as a home to Wiarton's premier manufacturing firm, this time under the name of Caframo Limited.

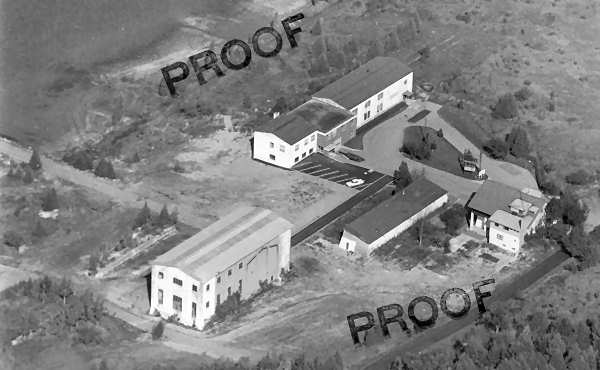

The Caframo factory incorporated some key elements of the old ruins (see Figure W6C and W6D below). The main storehouse for Caframo (with the name Caframo Ltd. in big letters in Figure W6D) was the original cement company Powerhouse (the roofline of the old boilerhouse was still visible on the rear exterior of the Caframo building). The walls of this building, although still standing after all the years of neglect, had to be carefully pulled back together using a series of cables. The wall closest to the shoreline had been leaning out by about three to four feet.

Caframo's manufacturing/office building (at left, below) incorporated the old stockhouse. The top left corner of the Rotary Building (as shown above in Figure W6B) was also used to construct a dwelling on the site (at rear centre in Figure W6C) while the three distict adjoined rectangles in the Rotary Building also survived as a separate building (front centre in Figure W6C). The remainder of the cement factory ruins were demolished and, along with some of the foundations of the old conveyor belt, used to build up the present pier. Upon close inspection of the pier, one can see examples of the solid construction of the cement works. Serveral examples are visible of huge century-old columns of cement with thick, twisted, protruding steel. A quiet reminder of what once stood just a short distance away.

During Caframo's first year of production in 1957, the factory operated out of the remains of the former Rotary Building (the three rectangle section in Figure W6C). Lack of adequate heating, however, led the company to move production into the northeast building constructed from the former stockhouse. In 1964, the manufacturing building was extended include more production and office space.

Figure W6C provides an excellent aerial view looking toward the back of the Caframo factory about 1964, shortly after the addition of the office portion of the building at the top of the image. Note the impression on the back of the largest building, the warehouse. As mentioned earlier, this building was the cement works powerhouse and the impression on the back is the outline of where the cement works boilerhouse once stood. Note also the foundations remaining at the left-bottom and left-top portions of the photo.

Figure W6C: Caframo Ltd. Factory (former Crown Portland Cement Co. buildings) - about 1964.

As an interesting sidenote, history had a strange way of repeating itself when the Town of Wiarton quickly moved to annex the former Cement Works property following the establishment of Caframo in 1954. The annexation was expected to save the company $1500 per year (about $14 000 in today's money) in electricity costs versus the rate charged in the Township of Keppel. In the end, however, the annexation was dismissed, just as it was 44 years earlier in the case of the Cement Works.

Having celebrated its sixty-fifth anniversary in 2020, Caframo still produces products such as fans, stirrers, and heaters. All of this is done on the site of its predecessor, the largest factory ever constructed in Wiarton, the Wiarton Cement Works.

Of note, in November and December of 2021, Caframo's warehouse (the former powerhouse and largest remaining building from the cement factory) was demolished. The condition of the building had deteriorated over time to the point where it was unsafe to use and cost prohibitive to repair. Figure W6D below shows a variety of images captured during the demolition ranging from November 17 to 23, 2021.

Figure W6D: Demolition of the Caframo warehouse and former Powerhouse of the Wiarton Cement Works (November 2021; source Caframo).

Figure W6E shows a time-lapse video from November 15 to December 15, 2021 as sourced from Caframo's webcam. In the end, the imposing walls of the structure were broken down into gravel and levelled across the land where it once stood.

Figure W6E: Demolition of the Caframo warehouse and former Powerhouse of the Wiarton Cement Works (November 14 to December 15, 2021; source Caframo).

The bright orange roof and bold black-on-white lettering of the company's name on the side of the building will be missed as a reference point to people around Colpoy's Bay. Moreover, it was the most obvious and impressive reminder of the former cement factory. That said other elements of the cement works remain standing and integrated into Caframo's existing structures, as explained above, while the remains of the massive rotary building and other structured demolished in the 1950s remain crumbled on top of what was once the world's longest conveyor belt. This provided the vantage point for 2004 image in Figure W6F. This is the Caframo layout I'll always remember.

Figure W6F: Caframo Ltd. Factory from the pier (former Crown Portland Cement Co. buildings) - 2004.